Machine Condition Monitoring Market to Hit USD 5.27 Billion by 2032, at a CAGR of 8.14% | SNS Insider

Machine Condition Monitoring Market Driven by demand for predictive maintenance, leveraging IoT and AI to enhance efficiency and reduce downtime in industries.

AUSTIN, TX, UNITED STATES, February 14, 2025 /EINPresswire.com/ -- Market Size & Industry Insights

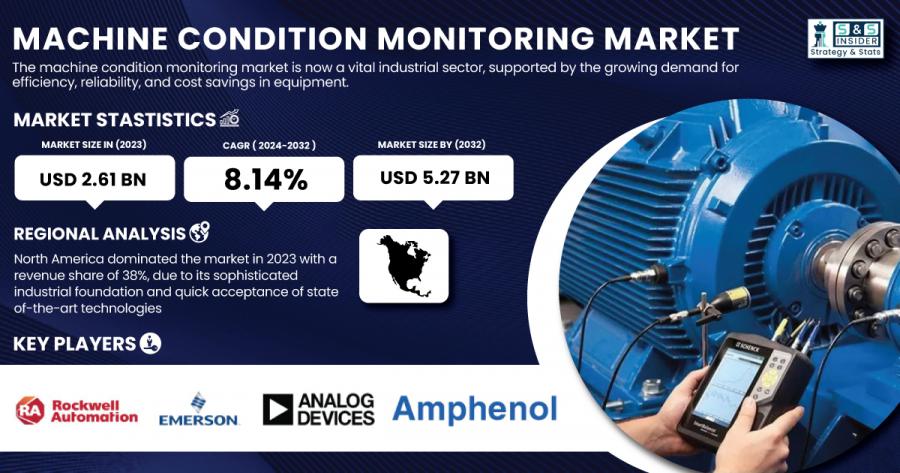

As Per the SNS Insider,“The Machine Condition Monitoring Market size was valued at USD 2.61 Billion in 2023and expected to reach USD 5.27 Billion by 2032, growing at a CAGR of 8.14% during 2024-2032.”

In 2023, leading vendors in the market offered advanced predictive maintenance solutions that incorporated emerging technologies such as AI, IoT, and real-time analytics to enhance equipment performance and reduce operational risks. Once again performance benchmarks showed improvements in the early faults detection leading to unplanned downtimes and lowered maintenance costs. Integration features varied by software platform, allowed for integration with enterprise asset management (EAM) and supervisory control and data acquisition (SCADA) systems. Adoption grew across sectors, including manufacturing, energy, and aerospace, with usage statistics from 2023 indicating increasing usage across industries, driven by a growing demand for asset reliability and operational efficiency.

Get Free Sample PDF of Machine Condition Monitoring Market (with Full TOC & Graphs) @ https://www.snsinsider.com/sample-request/1552

SWOT Analysis of Key Players as follows:

- Emerson Electric Co

- Rockwell Automation Inc

- Analog Devices Inc

- Amphenol Inc.

- National Instruments Corp

- Fluke Corporation

- General Electric

- Parker Hannifin Corp

- SKF

- Allied Reliability

- Meggitt PLC

Key Market Segmentation:

By Technique, vibration monitoring Dominating and ultrasound emission monitoring Fastest Growing

In 2023, vibration monitoring dominated the Machine Condition Monitoring Market, capturing 35% of the revenue share. This technique is crucial for detecting misalignments, imbalances, and mechanical issues in rotating equipment such as motors, pumps, and turbines. By analyzing vibration data, companies can predict equipment failures and perform maintenance before costly breakdowns occur. Industries like oil and gas, manufacturing, and power generation heavily rely on vibration monitoring to enhance efficiency and reduce downtime, with General Electric (GE) extensively using it in power plants to ensure turbine and generator reliability.

Ultrasound emission monitoring is expected to be the fastest-growing segment from 2024 to 2032, as it identifies early-stage faults and energy inefficiencies, which can be missed by other techniques. Widely used in compressed air systems, steam traps, and electrical equipment, ultrasound emission monitoring enables predictive maintenance and helps achieve sustainability objectives. Emerson Electric Co. integrates ultrasound technology into its machinery health solutions, helping automotive and aerospace industries identify leaks, bearing failures, and electrical faults efficiently.

Connect with Our Expert for any Queries @ https://www.snsinsider.com/request-analyst/1552

By Deployment, on-cloud dominating and on-premises Fastest Growing

In 2023, the on-cloud segment dominated the Machine Condition Monitoring Market with a 55% share, driven to its scalability, flexibility, and cost-effectiveness. Real Time Remote Monitoring with Cloud based solutions decrease machine status management time in conjunction with boosting efficiency by allowing for real time remote monitoring of plants. GE Digital utilizes cloud technology in its Predix platform, which collects and analyzes sensor data to provide predictive insights, helping industries optimize machine performance and prevent failures.

The on-premises segment is projected to grow at a faster CAGR during 2024-2032, as organizations prioritize data security and compliance by maintaining infrastructure control. On-premises solutions are favored in industries with strict regulatory requirements. Siemens offers robust on-site condition monitoring through its Siemens Condition Monitoring System, delivering in-depth diagnostics for industrial equipment.

By Process, online condition monitoring Dominating and portable condition monitoring Fastest Growing

In 2023, online condition monitoring held a dominant market share of over 54%, driven by to its potential to constantly monitor the machine, providing real-time analysis of important parameters such as vibration, temperature, and acoustic emissions. This approach incorporates devices to allow fault detection as ideas are embedded into real-world equipment, which helps to optimize the maintenance schedule while minimizing downtime. ongoing insights strengthens predictive maintenance strategies and minimizes unexpected failures.

Portable condition monitoring relies on handheld or mobile devices to assess equipment health at specific intervals rather than continuously. Commonly used for scheduled inspections, this method allows maintenance personnel to conduct detailed diagnostics across multiple machines without requiring a fixed setup.

By End Use, power generation Dominating and Chemical Fastest Growing

In 2023, the power generation segment led the market, due to high failure rates of critical components, costly repairs, and safety concerns, necessitating continuous machinery maintenance. The oil and gas sector is also gaining a significant share, driven by increasing demand for oil analysis, thermography, and vibration monitoring to enhance asset protection and efficiency.

The chemicals segment is set to register a high CAGR, due to the adoption of Industry 4.0, and the need for predictive maintenance and sustainability. Additionally, stringent regulations on worker safety and environmental compliance are compelling chemical plants to invest in advanced condition monitoring solutions.

Make an Inquiry Before Buying @ https://www.snsinsider.com/enquiry/1552

Regional Market Dynamics: North America’s Dominance & Asia-Pacific’s Rapid Growth

In 2023, North America led the Machine Condition Monitoring Market with a 38% revenue share, driven by its advanced industrial base and rapid adoption of cutting-edge technologies. Industries such as oil and gas, aerospace, and manufacturing have increasingly embraced predictive maintenance to reduce downtime and enhance operational efficiency.

Asia-Pacific is poised for the fastest growth from 2024 to 2032, fueled by rapid industrialization and infrastructure expansion in China, India, and Japan. Demand for condition monitoring solutions is on the rise, due to the region's manufacturing sector and an increased awareness of the benefits of predictive maintenance. Automotive, energy, and chemicals industries are investing significantly in these technologies to enhance efficiency and reduce operating costs.

Table of Content - Major Points Analysis

Chapter 1. Introduction

Chapter 2. Executive Summary

Chapter 3. Research Methodology

Chapter 4. Market Dynamics Impact Analysis

Chapter 5. Statistical Insights and Trends Reporting

Chapter 6. Competitive Landscape

Chapter 7. Machine Condition Monitoring Market Segmentation, by Technique

Chapter 8. Machine Condition Monitoring Market Segmentation, by Deployment

Chapter 9. Machine Condition Monitoring Market Segmentation, by Process

Chapter 10. Machine Condition Monitoring Market Segmentation, by Industry

Chapter 11. Regional Analysis

Chapter 12. Company Profiles

Chapter 13. Use Cases and Best Practices

Chapter 14. Conclusion

Continued…

Purchase Single User PDF of Machine Condition Monitoring Market Forecast Report @ https://www.snsinsider.com/checkout/1552

Akash Anand

SNS Insider

+1 415-230-0044

info@snsinsider.com

Distribution channels: Manufacturing

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release