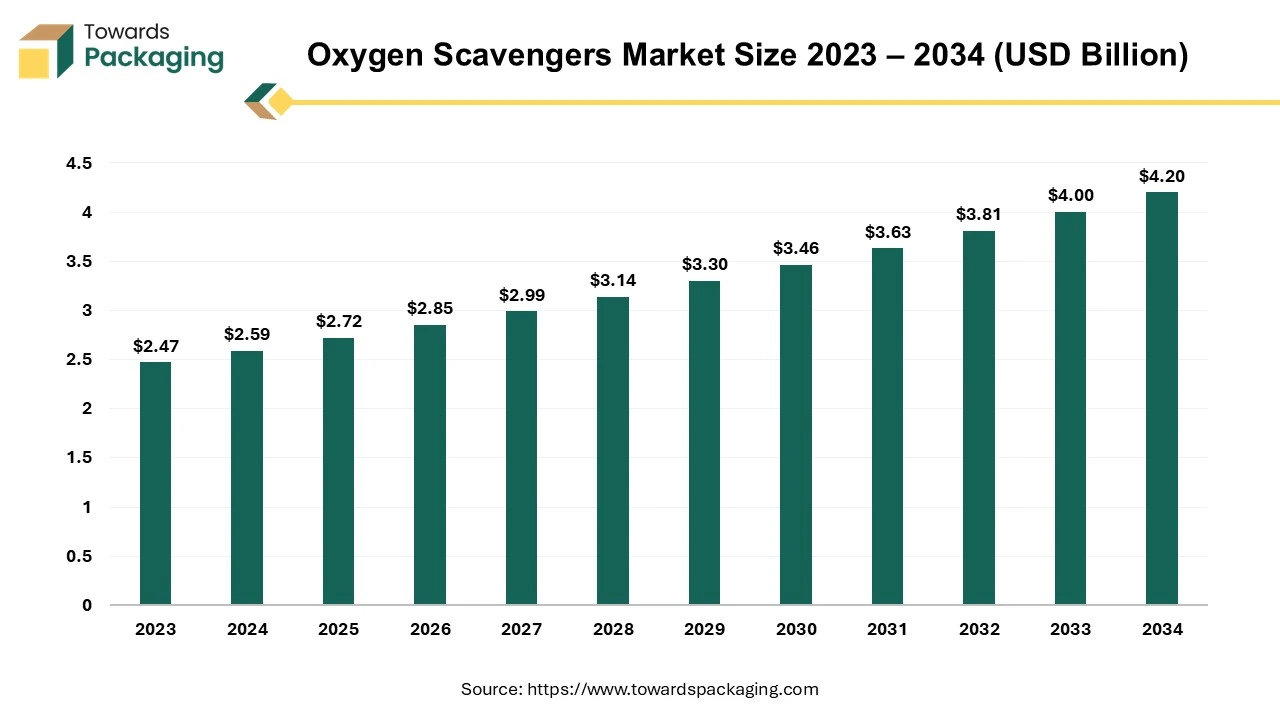

Oxygen Scavengers Market Size to Progress USD 4.20 Bn by 2034

According to Towards Packaging Consultants, the global oxygen scavengers market size stood at USD 2.59 billion in 2024 and is predicted to exceed USD 4.20 billion by 2034, experiencing a CAGR of 5% from 2024 to 2034.

/EIN News/ -- Ottawa, April 25, 2025 (GLOBE NEWSWIRE) -- The global oxygen scavengers market size to record USD 2.72 billion in 2025 and is projected to grow beyond USD 4.20 billion by 2034, a study published by Towards Packaging a sister firm of Precedence Research. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and collaboration to develop new technology for oxygen scavengers, which has estimated to drive the growth of the oxygen scavengers market in the near future.

Get All the Details in Our Solutions – Access Report Preview: https://www.towardspackaging.com/download-brochure/5487

Market Overview:

The use of oxygen scavengers or oxygen absorbers to enclosed packaging helps eliminate or lower the package's oxygen content. They are employed to prolong the shelf life and to ensure product safety. Numerous varieties of oxygen absorbers are available to meet a broad range of needs. Depending on the product's water activity, intended application, and other considerations, an oxygen absorber's components can change. In addition to being a component of packing films and structures, the oxygen absorber or scavenger is frequently contained in a porous sachet or packet. A polymer structure includes others.

The moisture in the surrounding air starts to seep into the iron particles inside the oxygen absorber sachet when the absorber is taken out of its protective packing. Iron is activated by moisture and oxidizes to produce iron oxide. Before the rusting process may start, the ambient air usually has to have a relative humidity of at least 65%. Sodium chloride is added to the mixture to aid in the oxidation process. It functions as an activator or catalyst, enabling the iron powder to oxidize even at relatively low humidity levels.

Major Key Trends in Oxygen Scavengers Market:

Growing Demand in Food & Beverage Industry

Growth in packaged and ready-to-eat foods has driven demand for oxygen scavengers to prevent spoilage and preserve freshness. Clean label trends are encouraging the use of food-safe and non-toxic scavenger materials.

Active & Intelligent Packaging

Integration of oxygen scavengers with smart packaging technologies (e.g., indicators for oxygen levels) is gaining traction. Active packaging solutions that respond to environmental changes are being adopted in pharmaceuticals and food sectors.

Eco-Friendly and Sustainability Materials

Shift toward biodegradable and recyclable oxygen scavenger materials. Regulations are pushing for non-metallic scavengers that are easier to dispose of and safer for the environment.

Growth in Pharmaceuticals Sector

The pharmaceutical industry uses oxygen scavengers to preserve drug potency and shelf life, especially for oxygen-sensitive compounds. Increased focus on compliance and safety in drug packaging is supporting market growth.

Technological Innovations

Development of advanced scavengers with faster reaction rates, higher efficiency, and longer life spans. New formulations (e.g., nano-based oxygen scavengers) are improving barrier properties.

Growth in Emerging Economies

Increasing urbanization and growth of middle-class populations in Asia-Pacific and Latin America are boosting demand for extended shelf-life products.

Customization and Application-Specific Solutions

Companies are offering tailored oxygen scavenger solutions for specific products and environmental conditions, enhancing performance and efficiency.

Limitations & Challenges in Oxygen Scavengers Market:

Cost Constraints

High production costs, especially for advanced or specialized scavengers (e.g., nano-based or pharmaceutical-grade), can be a barrier for small manufacturers. End users may opt for cheaper, less effective alternatives in cost-sensitive markets.

Safety and Regulatory Concerns

Stringent food safety and pharmaceutical regulations require thorough testing and approval processes. Some scavenger materials (especially metallic ones) may raise toxicity or migration concerns, limiting their use in direct contact with consumables.

Limited Reusability & Shelf Life

Many oxygen scavengers are single-use, becoming ineffective once activated. Pre-mature activation (e.g., due to humidity or accidental exposure to oxygen) can render the scavenger useless before it reaches the end product.

If there's anything you'd like to ask, feel free to get in touch with us @ sales@towardspackaging.com

Expansion of Healthcare & Pharmaceutical Packaging Drive Market Growth

Growing demand for sensitive drugs and biologics that degrade in oxygen-rich environments create a major need for scavengers. Oxygen scavengers can assist to ensure drug stability, efficacy, and compliance with stringent global pharmaceutical standards. Many modern pharmaceuticals, including vaccines, biologics, and injectables, are highly sensitive to oxygen. Oxygen can lead to oxidative degradation, minimizing drug potency, safety, and shelf life. Oxygen scavengers help maintain product stability without the need for preservatives or refrigeration in some cases. Global pharmaceutical supply chains demand extended shelf life to accommodate long transit times and storage in various conditions. Oxygen scavengers protect products in harsh climates or non-refrigerated environments. Hence, due to expansion of healthcare & pharmaceutical packaging it has estimated to create lucrative opportunity for the growth of the oxygen scavengers market in the near future.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

Regional Analysis

North America’s Large Consumer Base for Packaged Food to Promote Dominance

North America region held the largest share of the oxygen scavengers market in 2024, driven by the large consumer base for food & beverages and growing industrial sector in the region. North America region have large and mature processed and packaged food markets. Rising demand for ready-to-eat meals, convenience foods, and extended shelf life products boosts the utilization of oxygen scavengers in food packaging. North America region leads in carrying out research and development and clinical trials for pharmaceutical industry.

Growth of biopharma and strict U.S. Food and Drug Administration regulations on packaging integrity support increased scavenger usage. North America region is home to major players in the packaging and materials science sectors investing heavily in next-generation scavenger technologies, such as: intelligent packaging with oxygen indicator, multifunctional films with built-in oxygen absorption and nanotechnology-based scavengers. North American consumers demand freshness, safety, and quality in consumables and medications. Many leading global oxygen scavenger manufacturers and packaging firms have headquarters or major operations in North America, allowing for: faster innovation cycles, localized production and efficient distribution.

U.S. Oxygen Scavengers Market Trends

U.S. oxygen scavengers market is driven by the expanding processes & packaged food industry in the country. The U.S. leads in packaging and material science innovation, investing heavily in: Advanced oxygen scavenger formulations, Smart packaging (e.g., with oxygen indicators, and sensors) and Eco-friendly and nano-enabled scavengers. The U.S. has a massive ready-to-eat, frozen, and snack food market that relies heavily on oxygen scavengers to extend shelf life.

Asia’s Vast Area Under Pharmaceutical Industry to Support Growth

Asia Pacific region is seen to grow at the fastest rate in the oxygen scavengers market during the forecast period. Countries like China, India, Japan, and South Korea are seeing exponential growth in processed food consumption, creating a huge need for shelf-life extension using oxygen scavengers. Growth of generic drugs, vaccines, and exports from Asia Pacific drives demand for oxygen scavengers to ensure stability and compliance with international standards.

Low production costs and access to bulk raw materials make Asia Pacific an ideal region for large-scale manufacturing of oxygen scavengers. Many global players have set up manufacturing bases or joint ventures in Asia Pacific to reduce costs and serve local demand more effectively. Asia Pacific hosts a mix of international packaging giants and regional innovators, promoting competition and technological advancement.

China Oxygen Scavengers Market Trends

China oxygen scavengers market is driven by the China’s pharma sector upgrades which demand and align both with growth in advanced packaging technologies. China’s booming e-commerce platform has driven the market growth.

More Insights in Towards Packaging:

- Interactive Packaging Market Growth Driven by Innovation and Consumer Demand: https://www.towardspackaging.com/insights/interactive-packaging-market-sizing

- Packaging Design Services Market Strategic Analysis and Growth Opportunities: https://www.towardspackaging.com/insights/packaging-design-services-market-sizing

- Cash Transport Security Bags Market Growth, Innovations, and Market Size Forecast 2034: https://www.towardspackaging.com/insights/cash-transport-security-bags-market-sizing

- Microwave Packaging Market Scenario Planning & Strategic Insights for 2034: https://www.towardspackaging.com/insights/microwave-packaging-market-sizing

- Material-Neutral Packaging Market Growth Drivers, Challenges and Opportunities: https://www.towardspackaging.com/insights/material-neutral-packaging-market-sizing

- Wet Glue Labels Market Emerging Trends, Investment Opportunities and Competitive Benchmarking: https://www.towardspackaging.com/insights/wet-glue-labels-market-sizing

- Food Labels Market Emerging Trends, Investment Opportunities and Competitive Benchmarking: https://www.towardspackaging.com/insights/food-labels-market-sizing

- Mono-material Plastic Packaging Film Market Playbook, Growth Opportunities and Trends: https://www.towardspackaging.com/insights/mono-material-plastic-packaging-film-market-sizing

- Smart Labels Market Outlook Scenario Planning and Strategic Insights for 2034: https://www.towardspackaging.com/insights/smart-labels-market-sizing

- Paperboard Packaging Market Research, Consumer Behavior, Demand and Forecast: https://www.towardspackaging.com/insights/paperboard-packaging-market-sizing

Segment Outlook

Type Insights

The metallic type segment dominated the oxygen scavengers market with the largest share in 2024. Metallic-type oxygen scavengers, particularly those based on iron powder, are used extensively in packaging because they offer several advantages for preserving the quality and shelf life of products. Metallic oxygen scavengers, like iron-based sachets, react with oxygen to form iron oxide (rust). This is a highly efficient and fast reaction, reducing oxygen levels to very low ppm (parts per million) in sealed environments. By removing oxygen, they prevent oxidation, which can cause spoilage, rancidity, discoloration, and loss of nutrient especially in food products. They're also useful in pharmaceuticals, electronics, and other oxygen-sensitive goods.

Typically placed inside sachets or embedded in packaging layers, they don’t mix with the product, making them safe and easy to use. Iron powder is relatively cheap, abundant, and non-toxic, making it a practical option for mass production. It doesn’t produce harmful byproducts, so it’s considered safe for food contact (when properly packaged). Widely approved by regulatory bodies (like FDA in the U.S.) for use in food packaging, especially in dry, low-moisture products.

The non-metallic type segment is anticipated to witness lucrative growth during the forecast period. Non-metallic oxygen scavengers are seeing the fastest growth in the oxygen scavenger market due to several key trends and advantages they offer over traditional metallic (usually iron-based) systems. Non-metallic scavengers (like those based on ascorbic acid, enzymes, or polymer-based systems) can be integrated directly into packaging films. This allows for clear, flexible, and aesthetically appealing packaging, which is increasingly in demand especially for premium or retail-ready products. Unlike iron-based scavengers, non-metallic types don’t rust or corrode, making them safer for moist or high-humidity environments, like ready-to-eat meals or beverages.

Many non-metallic options are eco-friendlier and can be designed to be recyclable or compostable, aligning with global sustainability trends. There’s growing pressure from both consumers and regulators for greener packaging solutions. Suitable for high-moisture or liquid products where metallic scavengers would be ineffective or could pose safety risks. Also used in medical and pharmaceutical packaging, where metal contamination is unacceptable. Advancements in materials science have led to smart and multifunctional films that include oxygen scavenging capabilities along with moisture control, antimicrobial properties, or UV protection. In some markets, metal-based sachets are restricted or discouraged due to safety labelling, consumer perception, or export regulations. Non-metallic scavengers are often less obtrusive, both visually and functionally, supporting cleaner branding.

End-use Insights

The food & beverages segment dominated the oxygen scavengers market with the largest share in 2024. Oxygen leads to oxidation of fats, oils, and certain nutrients, causing rancidity, off-flavours, and color changes. Scavengers remove oxygen, slowing or preventing these unwanted chemical reactions. With less oxygen, food stays fresher for longer without needing preservatives. Critical for items like snacks, nuts, coffee, dairy, meats, and baked goods. Many spoilage organisms (like molds and aerobic bacteria) require oxygen to grow. Reducing oxygen creates an unfriendly environment for these microbes, enhancing food safety. Oxygen can degrade sensitive vitamins like A, C, and E. Scavengers help retain the nutritional value of fortified or fresh products.

Oxygen scavengers allow producers to avoid or reduce chemical preservatives, which consumers often want to avoid. This supports trends like "clean label" or "natural" products. Oxygen scavengers is used in modified atmosphere packaging (MAP) and vacuum packaging, scavengers provide an added layer of protection, especially during transport or storage. Oxygen scavengers can be utilized as labels, sachets, or integrated into films, giving brands flexibility in packaging design.

The pharmaceuticals segment is anticipated to witness lucrative growth during the forecast period. Many active pharmaceutical ingredients (APIs) are oxygen-sensitive. Exposure to oxygen can lead to loss of potency, chemical changes, or formation of harmful byproducts. Oxygen scavengers help to maintain stability and efficacy over the product’s shelf-life. By minimizing oxygen inside the packaging, scavengers extend the usable life of medications, reducing waste and ensuring long-term availability.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results—schedule a call today: https://www.towardspackaging.com/schedule-meeting

Recent Breakthroughs in Global Oxygen Scavengers Market:

Avient Corporation has developed and launched an oxygen-scavenging additive that is said to increase the shelf life of goods in PET containers and packaging without affecting their ability to be recycled. ColorMatrix Amosorb 4020L is a non-nylon-based additive that can be used in PET bottles with up to 100% recycled material. Therefore, firms that want to enhance the amount of recyclable material in their packaging are advised to do so. In a range of dose levels, it is intended to prolong the shelf life of condiments, sauces, juices, beverages (including some alcoholic ones), and other applications.

Global Oxygen Scavengers Market Segments

By Type:

- Metallic

- Non-metallic

By End-use:

- Food & Beverage

- Pharmaceuticals

- Chemicals

- Oil & Gas

By Region:

-

North America

- U.S.

- Canada

-

Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

-

Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

-

Latin America

- Brazil

- Mexico

- Argentina

-

Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait

Global Oxygen Scavengers Market Players

- Mitsubishi Gas Chemical Company Inc.

- Arkema

- Solvay America Inc.

- BASF SE

- Clariant

- Kemira

- SUEZ

- Solenis

- Chardon Laboratories, Inc.

- QualiChem Technologies

- Chemco Industries, Inc.

- Lubchem

Invest in Premium Global Insights @ https://www.towardspackaging.com/price/5487

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Our Trusted Data Partners:

Precedence Research | Statifacts |Towards Automotive | Towards Healthcare | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Webwire | Packaging Webwire | Automotive Webwire

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Distribution channels: Consumer Goods ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release