ExSorbtion announces acquisition of SRI International’s novel Direct Lithium Extraction technology

ExSorbtion is transforming lithium recovery with cutting-edge innovation to deliver cost-effective and sustainable solutions for the clean energy transition

SUNNYVALE, CA, UNITED STATES, December 16, 2024 /EINPresswire.com/ -- Transforming Sustainable Lithium Recovery with Cutting-Edge InnovationExSorbtion, a leader in advanced lithium extraction technologies, is excited to announce the acquisition of SRI International’s revolutionary Direct Lithium Extraction (DLE) technology.

This game-changing patented technology features unique manganese-based metal ion imprinted polymer sorbents and a novel carbon dioxide-based regeneration process, delivering superior efficiency, sustainability, and cost-effectiveness for lithium recovery.

Breakthrough Lithium Extraction Technology

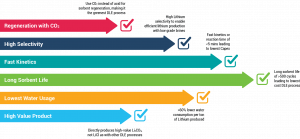

SRI’s patented DLE technology employs manganese-based sorbents comprised of nanoparticles with a porous composite structure. Key features include:

• Dual Active Zones: The sorbents combine a lithium-selective metal ion sieve and an imprinted polymer binder, enabling efficient lithium-ion uptake and separation from competing ions.

• Superior Performance: The combination provides high lithium recovery rates, fast kinetics, and effective ion separation, setting it apart from other sorbent-based DLE technologies that rely on single-system sorbents.

• Eco-Friendly Regeneration Process: Unlike traditional methods that use hydrochloric acid, SRI’s process utilizes carbon dioxide gas for sorbent regeneration. This dramatically extends sorbent life to over 500 cycles while reducing environmental impact and producing lithium carbonate directly, eliminating costly intermediate steps.

A Greener, Cost-Effective Solution for Lithium Extraction

The carbon dioxide-based regeneration process offers a breakthrough in sustainability by:

• Extending Sorbent Life: The patented process reduces the sorbent's capacity loss to near-zero, far surpassing the 30–50 cycles typical of acid-based systems.

• Lowering Costs: By maximizing sorbent life, ExSorbtion’s DLE process significantly reduces the cost of goods sold (COGS), where sorbents account for over 30% of operational expenses.

• Environmental Benefits: Acting as a carbon sink, the process can utilize captured carbon dioxide while consuming less fresh water compared to other DLE methods, making it the greenest DLE process available today.

“With the acquisition of SRI’s patented Direct Lithium Extraction technology, ExSorbtion is revolutionizing lithium recovery to meet the surging demand for this critical resource,” said Anupam Ghildyal, President of ExSorbtion. “Our innovative approach positions us to deliver the most cost-effective and sustainable solutions for the clean energy transition.”

Driving the Clean Energy Future

ExSorbtion is committed to advancing the sustainable production of lithium, a vital element for electric vehicles, renewable energy storage, and consumer electronics. By integrating SRI’s cutting-edge technology, ExSorbtion is poised to lead the DLE market with innovative, scalable, and eco-friendly solutions.

About SRI International:

SRI International (SRI) is a nonprofit scientific research institute and organization headquartered in Menlo Park, California, United States. It was established in 1946 by trustees of Stanford University to serve as a center of innovation to support economic development in the region. The organization was founded as the Stanford Research Institute. SRI formally separated from Stanford University in 1970 and became known as SRI International in 1977.

For nearly 80 years, SRI researchers have led the discovery and design of groundbreaking products, technologies, and industries – collaborating across technical and scientific disciplines and bringing innovations to the marketplace through research as a service, spin-off ventures, new product solutions, and technology licensing. Whether it is through the development and creation of Arpanet, Siri, tele-robotics technologies, or cancer treatments, SRI innovations continue to deliver technology to address the world’s most complex and urgent challenges.

About ExSorbtion:

ExSorbtion’s mission is to become the highest-value supplier of lithium to enable the electrification of everything. ExSorbtion has acquired and is commercializing a technology developed by SRI International for Direct Lithium Extraction (DLE). This technology portfolio includes patented sorbents that have demonstrated very high lithium selectivity and fast reaction time to adsorb lithium from the brine and to remove lithium from the sorbent. The patented regeneration process uses carbon dioxide gas instead of acid (used by all other DLE companies) to extract the adsorbed lithium from the sorbents.

By using gas instead of acid, ExSorbtion’s sorbents last more than 10 times longer than competing manganese- and titanium-based sorbents – which is essential since the cost of the sorbent is over 30% of the overall cost of goods sold for the DLE process, enabling ExSorbtion to offer potentially the lowest operating cost compared to other DLE processes. Additionally, since the process uses carbon dioxide gas for regeneration, the process acts as a carbon sink, making it the greenest DLE process while consuming a significantly lower amount of fresh water than competing DLE processes.

Media Contact

Contact Us

Engagement Manager

ExSorbtion Inc.

hello@exsorbtion.com

Visit us on social media:

X

LinkedIn

Distribution channels: Automotive Industry, Energy Industry, Environment, Manufacturing, Mining Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release